Understanding CNC Cabinet Software: Best Cnc Cabinet Software

CNC cabinet software is a powerful tool that revolutionizes the cabinetmaking process, enabling efficient design, fabrication, and assembly. It empowers cabinetmakers to create intricate and customized designs, optimize material usage, and streamline production workflows.

Benefits of Using CNC Cabinet Software

CNC cabinet software offers a range of benefits that enhance efficiency, accuracy, and productivity in cabinetmaking.

- Enhanced Design Capabilities: CNC cabinet software provides advanced design tools that enable cabinetmakers to create detailed and intricate designs with ease. Users can incorporate complex shapes, curves, and intricate details, allowing for greater creative freedom and personalized designs.

- Improved Accuracy and Precision: CNC cabinet software ensures precise dimensions and cuts, eliminating the possibility of human error. This accuracy translates to perfect-fitting cabinets and a professional finish.

- Optimized Material Usage: CNC cabinet software utilizes advanced nesting algorithms to optimize material usage, minimizing waste and reducing material costs. This feature is particularly beneficial for projects that require large quantities of material.

- Streamlined Production Workflows: CNC cabinet software integrates seamlessly with CNC machines, enabling automated cutting, drilling, and routing operations. This automation streamlines production processes, reducing manual labor and increasing efficiency.

- Reduced Lead Times: By automating many tasks, CNC cabinet software significantly reduces lead times, allowing cabinetmakers to complete projects faster and meet deadlines more effectively.

Types of CNC Cabinet Software

CNC cabinet software comes in various forms, each catering to specific needs and budgets.

- Standalone Software: Standalone software packages offer comprehensive features for design, fabrication, and assembly, providing a complete solution for cabinetmaking. These packages are often more expensive but offer greater flexibility and control.

- Cloud-Based Software: Cloud-based software solutions are accessible from any internet-connected device, allowing for collaboration and remote access. These solutions are often more affordable than standalone packages but may have limitations in terms of functionality.

- Specialized Software: Some software packages are specifically designed for particular cabinetmaking applications, such as kitchen cabinets, bathroom vanities, or custom furniture. These specialized packages offer features tailored to the specific requirements of the application.

Features and Functionalities of CNC Cabinet Software

CNC cabinet software is packed with features and functionalities that enhance the cabinetmaking process.

- Design Tools: CNC cabinet software offers a wide range of design tools, including drawing tools, 3D modeling capabilities, and libraries of pre-designed cabinet components. These tools enable cabinetmakers to create detailed and customized designs with ease.

- Material Optimization: Advanced nesting algorithms optimize material usage, minimizing waste and reducing costs. This feature is crucial for maximizing efficiency and profitability.

- CNC Machine Integration: CNC cabinet software integrates seamlessly with CNC machines, enabling automated cutting, drilling, and routing operations. This integration streamlines production processes and improves accuracy.

- Assembly Instructions: Some software packages generate detailed assembly instructions, ensuring accurate and efficient assembly. This feature is particularly helpful for complex cabinet designs.

- Project Management: CNC cabinet software can manage projects effectively, tracking progress, scheduling tasks, and providing real-time updates. This feature helps to keep projects on track and within budget.

Key Features to Consider

Choosing the right CNC cabinet software is crucial for efficient and accurate production. It’s not just about the price tag, but also about the features that will help you streamline your workflow and achieve the desired results. Several key features deserve careful consideration.

Design and Visualization Capabilities, Best cnc cabinet software

Powerful design and visualization tools are essential for creating detailed and accurate cabinet designs. These features enable you to:

- Create 3D models: This allows you to visualize the final product, identify potential design flaws, and make necessary adjustments before production.

- Import and export various file formats: This ensures compatibility with other design software and allows for seamless collaboration with clients and other stakeholders.

- Utilize libraries of pre-designed components: These libraries can save you time and effort by providing readily available elements such as doors, drawers, and shelves.

- Customize designs with ease: Flexible design tools enable you to modify existing components or create entirely new ones, ensuring your designs are unique and meet specific customer requirements.

CAM (Computer-Aided Manufacturing) Features

CAM features translate your design into machine-readable instructions, ensuring accurate and efficient production. Key considerations include:

- Toolpath generation: The software should generate optimal toolpaths for your CNC machine, minimizing cutting time and maximizing material utilization.

- Simulation capabilities: This feature allows you to simulate the cutting process, identifying potential collisions or issues before actual production begins.

- Support for various CNC machine types: The software should be compatible with your specific CNC machine and offer customization options for different machine configurations.

- Automatic optimization of cutting parameters: This ensures optimal cutting speed, feed rate, and tool selection, leading to improved production efficiency and quality.

Material Management and Nesting Tools

Efficient material management is critical for minimizing waste and maximizing profitability. This is where nesting tools come into play.

- Material library: The software should have a comprehensive library of materials, including different types of wood, laminates, and other materials commonly used in cabinetmaking.

- Nesting optimization: This feature automatically arranges cabinet parts on the material sheet, minimizing waste and maximizing material utilization. This can lead to significant cost savings, especially for larger projects.

- Material tracking and inventory management: This allows you to monitor your material stock, track usage, and identify potential shortages, ensuring smooth production flow.

Automation and Optimization Functions

Automating repetitive tasks and optimizing production processes can significantly improve efficiency and reduce errors.

- Automated parts labeling and drilling: This eliminates the need for manual labeling and drilling, saving time and ensuring accuracy.

- Automated bill of materials (BOM) generation: The software should automatically generate a BOM based on your design, ensuring accurate material ordering and production planning.

- Production scheduling and tracking: These features allow you to monitor production progress, identify bottlenecks, and make necessary adjustments to optimize production flow.

Popular CNC Cabinet Software Options

Choosing the right CNC cabinet software is crucial for efficient and accurate cabinet production. The software you select should align with your specific needs, budget, and project complexity. Here, we explore some of the most popular CNC cabinet software options available, comparing their features, pricing, and user experiences.

Top CNC Cabinet Software Programs

These programs are widely used in the cabinetmaking industry, offering a range of features and capabilities to streamline the design and production process.

- Cabinet Vision: Cabinet Vision is a comprehensive software solution that caters to both small and large cabinet shops. It provides powerful design tools, advanced features for creating complex cabinets, and seamless integration with CNC machines. Cabinet Vision excels in its ability to handle intricate details, custom designs, and large-scale projects.

- Vectric VCarve Pro: VCarve Pro is a popular choice for its user-friendly interface and affordability. It offers a wide range of design and machining tools, making it suitable for both beginners and experienced users. VCarve Pro is known for its ease of use, intuitive design tools, and effective 2D and 3D modeling capabilities.

- SolidWorks: SolidWorks is a powerful 3D CAD software widely used in various industries, including cabinetmaking. It provides advanced modeling capabilities, detailed design features, and seamless integration with CNC machines. SolidWorks is a robust solution for complex projects, intricate designs, and high-precision manufacturing.

- Autodesk Inventor: Autodesk Inventor is another powerful 3D CAD software that offers a comprehensive set of tools for designing and manufacturing cabinets. It provides advanced features for creating complex designs, generating detailed drawings, and integrating with CNC machines. Autodesk Inventor is known for its versatility, advanced modeling capabilities, and integration with other Autodesk products.

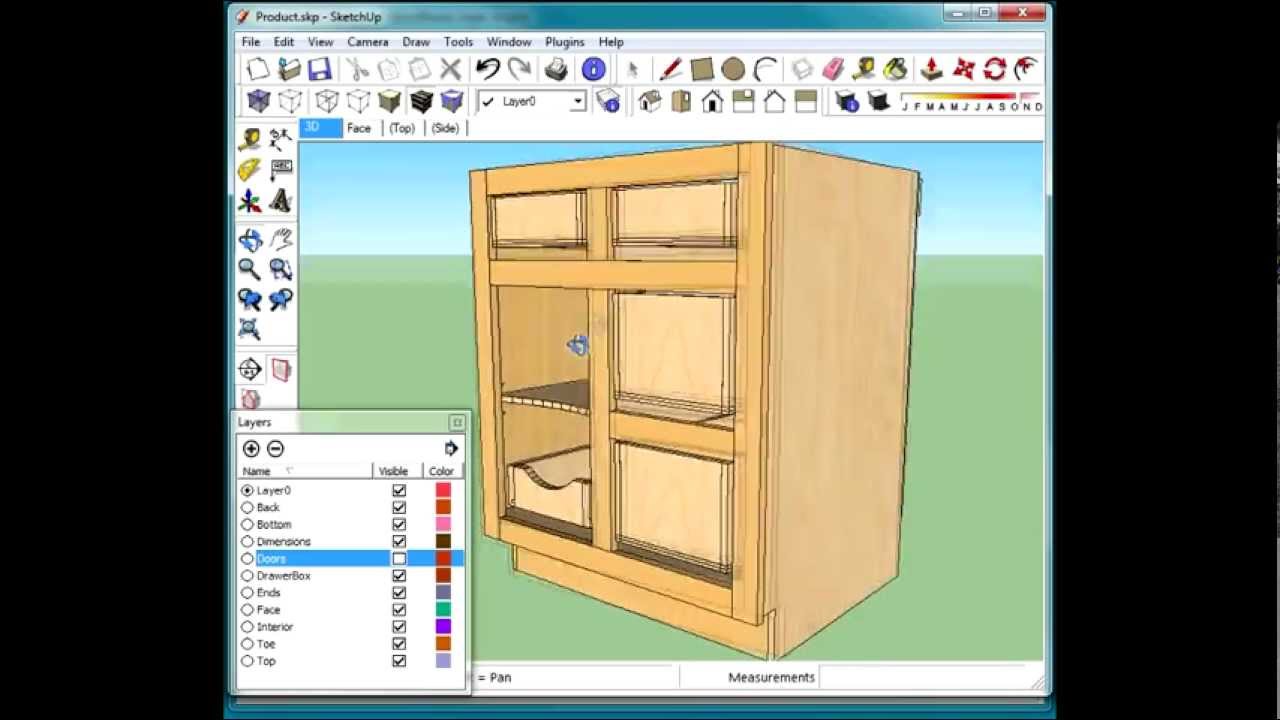

- SketchUp: SketchUp is a user-friendly 3D modeling software that is popular for its intuitive interface and ease of use. While primarily known for its architectural applications, SketchUp can be effectively used for cabinet design. Its simplicity and intuitive tools make it suitable for beginners, while its advanced features can handle complex projects.

Software Comparison

Each software program offers unique features, pricing models, and user experiences. Here’s a comparison of their key aspects:

- Features:

- Cabinet Vision: Advanced design tools, complex cabinet creation, detailed drawings, seamless CNC integration, and project management features.

- Vectric VCarve Pro: User-friendly interface, 2D and 3D modeling, intuitive design tools, various machining options, and affordable pricing.

- SolidWorks: Powerful 3D modeling, advanced design features, detailed drawings, seamless CNC integration, and extensive customization options.

- Autodesk Inventor: Comprehensive 3D modeling, detailed design features, advanced machining capabilities, seamless CNC integration, and integration with other Autodesk products.

- SketchUp: User-friendly interface, intuitive design tools, basic 3D modeling, and affordable pricing.

- Pricing:

- Cabinet Vision: Offers subscription-based pricing with varying tiers based on features and support levels.

- Vectric VCarve Pro: Offers a one-time purchase price with affordable options for individual users and businesses.

- SolidWorks: Offers subscription-based pricing with varying tiers based on features and support levels.

- Autodesk Inventor: Offers subscription-based pricing with varying tiers based on features and support levels.

- SketchUp: Offers free and paid subscription-based options with varying features and support levels.

- User Experience:

- Cabinet Vision: Offers a comprehensive user experience with a wide range of features, but can be complex for beginners.

- Vectric VCarve Pro: Offers a user-friendly experience with intuitive tools, making it suitable for both beginners and experienced users.

- SolidWorks: Offers a powerful user experience with advanced features and customization options, but can be complex for beginners.

- Autodesk Inventor: Offers a comprehensive user experience with advanced features and customization options, but can be complex for beginners.

- SketchUp: Offers a simple and intuitive user experience, making it suitable for beginners and those seeking a user-friendly design tool.

Successful Projects

These software programs have been used to create a wide range of successful cabinet projects:

- Cabinet Vision: Cabinet Vision has been used to design and manufacture complex custom cabinets for luxury homes, high-end retail stores, and commercial spaces.

- Vectric VCarve Pro: Vectric VCarve Pro has been used to create intricate designs for furniture, custom cabinetry, and decorative woodworking projects.

- SolidWorks: SolidWorks has been used to design and manufacture high-precision cabinets for medical equipment, aerospace components, and industrial applications.

- Autodesk Inventor: Autodesk Inventor has been used to design and manufacture a wide range of cabinets for various industries, including automotive, aerospace, and consumer goods.

- SketchUp: SketchUp has been used to design and manufacture cabinets for residential projects, small businesses, and DIY enthusiasts.

Strengths and Weaknesses

Each software program has its own strengths and weaknesses, which are important to consider when making a selection.

- Cabinet Vision:

- Strengths: Powerful design tools, advanced features, seamless CNC integration, excellent support.

- Weaknesses: Can be complex for beginners, high cost, steep learning curve.

- Vectric VCarve Pro:

- Strengths: User-friendly interface, affordable pricing, wide range of features, excellent support.

- Weaknesses: Limited advanced features compared to other options.

- SolidWorks:

- Strengths: Powerful 3D modeling, advanced features, seamless CNC integration, extensive customization options.

- Weaknesses: Can be complex for beginners, high cost, steep learning curve.

- Autodesk Inventor:

- Strengths: Comprehensive 3D modeling, advanced features, seamless CNC integration, integration with other Autodesk products.

- Weaknesses: Can be complex for beginners, high cost, steep learning curve.

- SketchUp:

- Strengths: User-friendly interface, intuitive design tools, affordable pricing, large community support.

- Weaknesses: Limited advanced features, basic 3D modeling capabilities.

Imagine crafting intricate cabinets with precision and ease using the best CNC cabinet software. The possibilities are endless, from sleek modern designs to classic traditional styles. Think of creating a stunning focal point for your bedroom, like the exquisite bedroom desk by Ashley , but with your own unique touch.

With the right software, you can transform your woodworking dreams into reality, building cabinets that are both beautiful and functional.

Imagine crafting the perfect cabinetry for a jack and jill style bedroom , where every detail, from the intricate carvings to the smooth, flowing lines, is a testament to your craftsmanship. The best CNC cabinet software can help you bring this vision to life, allowing you to design and create bespoke cabinets that are as unique as the space they inhabit.